What is Servo Motor?

Electric motors have various categories and models. Each of these categories causes the engine to accommodate a series of special applications. A Servo motor is a practical and special tool that is designed to complete precise and sensitive operations. Having high sensitivity and good speed and accuracy can be identified as the most important features of this product. The servo motor is connected to special electronic circuits such as drives and can provide rotation to the circuit. It should be noted that the control of the acceleration angle, speed, etc. is done by the instruments placed in the circuit.

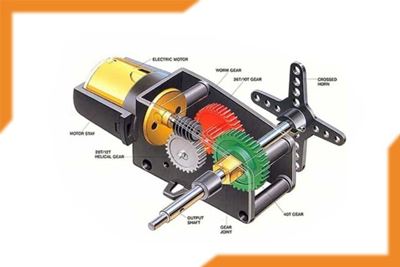

Servo motors are designed to rotate at various speeds and angles. Depending on the needs of the project, you can completely determine the speed of operation and the way of rotation of this device. These products are generally sold in two main categories, i.e. models with gearbox and without gearbox in the market. Having different sizes and different functions can be identified as another key feature of this product. Many robotics projects use this engine. Servo motor consists of different parts. This issue has allowed this product to work using various methods. Having feedback specific to the position of the coupler can be identified as another important feature of this product.

Types of servo motors

Servo motors can be sold in various categories in the market. All types of servo motors are designed to accommodate specific operations. In terms of application, servo motors are classified into two categories, AC and DC. Each of these engine categories also has thirty particular applications. Of course, there are other methods to analyze and categorize this product.

Analysis based on workflow, commutation, and rotor rotation can be identified as the most essential methods of categorizing this product. Based on the course of the rotor, these products are sold in two categories: synchronous or asynchronous. Based on the commutation category, these products will be available to applicants in two categories with or without a broom.

AC or DC servo motors

AC or DC servo motors will need various electric powers to operate. The engines used in this device can have various categories. AC motors draw more current and are more common in industrial and heavy-duty situations. DC models, on the other hand, are designed to draw more current and be used in lighter projects instead. Robotics projects, portfolios, and laboratories can be identified as the most important situations for using this product.

With or without a broom

Using or not using a brush can be identified as another factor in the classification of servo motors. This category is usually only related to DC motors. AC motors will be classified based on another factor i.e. speed and mode of operation. In general, the existence of a vacuum cleaner in an engine can affect the entire structure of the project. DC motors usually perform commutation mechanically by using a commutator. Sometimes these motors complete this process electronically without brushes. Motors that have a brush are cheaper and more efficiency. As a result, they are more reliable for a variety of projects.

Read more: What is the cause of servo motor failure?

Classification of movement and speed

The last method of classifying servo motor types is related to the speed of movement and the way of movement. As mentioned, these products are sold in the market in two main categories, i.e. synchronous and asynchronous models. This category is usually used for AC motors. AC motors determine their speed by the frequency of the source. When the speed of the motor is the same as the frequency, the motor is synchronous. When the speed is not the same as the frequency, the motor becomes asynchronous. Paying attention to this issue can directly affect your project. Because synchronous motors are designed to allow you to manage speed based on frequency.

Encoder stepper motor

Stepper servo motor can be divided into three main categories, i.e. with brake, encoder and normal. Each of these stepper categories and models has a series of special features. Stepper motor with encoder can be identified as one of the most common stepper models, which has attracted many fans due to having a series of special and key features.

Note that this stepper can easily determine the performance of the motor. This issue has allowed it to become very popular. Among the most important things that you should pay attention to when buying an encoder stepper motor is the type of circuit and how it is designed. Many buyers choose the wrong drive when buying this product or do not calculate the flange and torque accurately.

Types of servo motor movement

Servo motors are produced in different sizes and types, and in this section we will examine their classification in terms of movement. There are three types of movements for servo motors:

Positional rotation is continuous and linear rotation. Positional Rotation Servos have the ability to rotate 180 degrees. They also have stop mechanisms that protect the output shaft from over-rotation.

Continuous rotation servo motor is a servo whose range of motion is not limited. Instead of letting the input signal determine which position the servo should rotate, continuous servo rotation relates the input to the output speed and direction. The infinite motion of these motors allows them to move in both CW and CCW directions.

Linear servos use rack and pinion mechanism to change their function. A rack and pinion (gear and shoulder) converts rotary motion into linear motion.