What is PLC? And what are its uses?

plc stands for Programmable Logic Controller and is a type of programmable logic controller. Today, this controller plays an important role in the management and planning of industrial sectors and leads to better management of processes in this sector.

PLCs are based on microprocessors, and by having components such as timers, counters, and transfer constants, they make it easy to control complex processes.

The input information is received through the sensors and stored in the memory, this information is processed according to the commands in the memory and then the outputs are made properly. Each PLC has its programming language, which is the interface between the user and the PLC hardware. The most important PLC programming methods are the ladder method, flowchart method, and sentence list method, which we will examine in the following articles.

PLCs have different types and brands, Siemens and Delta PLCs are among the most famous PLC brands in the country.

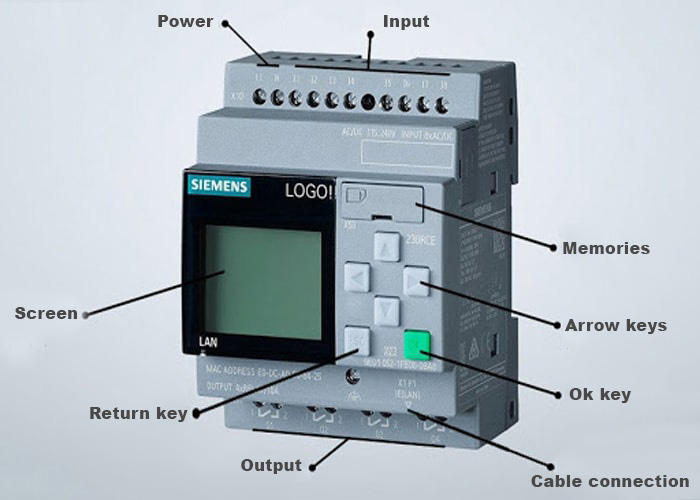

Main components of PLC

The main parts of PLC include the following five parts:

1- Power source

As an electronic device, the PLC processor receives its required power from the power source. The power supply is also responsible for reducing fluctuations and reducing the received noise level.

2- CPU

CPU (Central Processing Unit) after receiving programming commands

an analysis of received data creates appropriate control outputs and prevents errors by continuously checking PLC performance.

3- Input unit and output unit

These two parts are responsible for communication with the surrounding environment.

A) Input unit: receives the output information of sensors and switches and sends it to the CPU for processing.

b) Output unit: the final command signals from this unit are sent to other equipment and the control process takes place.

4- Memories

Programmed commands and information received from the input unit are stored in memories.

5- Software

In the software section, the desired control philosophy is designed and downloaded to the PLC hardware with interface cables.

What are the different types of PLCs?

In general, PLCs are divided into two main categories

• Compact (Compact PLC)

• Modular (Modular PLC)

are divided

Compact PLCs have a fixed number of input/output modules and there is no ability to expand modules.

But in modular PLCs, the number of input/output modules can be expanded.

What are the advantages of PLC?

As it was said, the use of PLC leads to better management of an industrial machine. The use of PLC has made the traditional methods of managing machines obsolete, and human labor is no longer needed, and these machines work automatically using PLC commands.

In general, the advantages of plc are:

1- The use of PLC reduces the volume of control panels.

2- The use of PLC saves a lot of money.

3- PLC does not have mechanical consumption, so in addition to longer life, it does not need periodic service and repairs.

4- PLC energy consumption is much less than relay circuits.

5- PLC does not create audio and electrical noises.

6- Troubleshooting control circuits with PLC is quick and easy and usually, PLC itself has a troubleshooting program.

What are the uses of plc?

Among the most important applications of PLC, the following can be mentioned:

• Automotive industry (paint spraying systems, drilling systems, parts connection systems, parts, and equipment testing systems, automatic presses, etc.)

• Chemical industries (used in devices that combine materials, mixing systems, etc.)

• Plastic manufacturing industries (used in air-blowing systems, plastic analysis production systems, etc.)

• Food industry (packaging, extracting, etc.)

• Steel and iron smelting industries

• Transportation industries (transportation equipment, conveyors, etc.)

• Construction industry (automatic lighting, elevator, air control)

• Energy conversion industries (gas recycling systems, waste recycling, gas pressure boosting stations, etc.)

• And in general, most industrial machines

How is PLC programming?

A computer with dedicated PLC software is used for PLC programming. The most widely used form of programming is ladder logic. In this logic, instead of words, symbols are used to simulate the logic control of the relay. These symbols are connected by lines to show the current through the connections and coils. The completed program looks like a ladder but represents an electrical circuit. So if you can understand how basic electrical circuits work, you can understand ladder logic.

An example of a PLC application

Suppose we want to turn on and off a light bulb with a switch. We can do this with a switch and a light bulb. It's simple, we act as shown below!

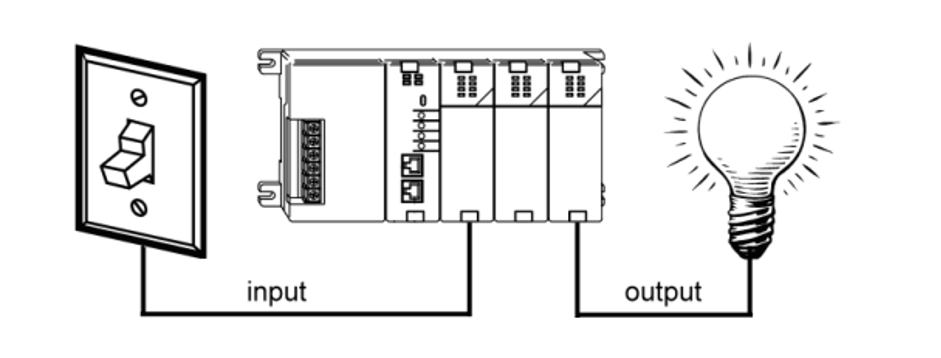

Suppose we want the lamp to turn on with a delay of 20 seconds after pressing the key, we need to buy a timer and change the connections. But instead of doing this, we act as shown below and put the key in the input of a PLC and the lamp in its output.

It is enough to apply a 20-second delay in the PLC. The operation was carried out without any changes in the main circuit!

But consider a system thousands of times more complex than a light bulb and a switch. Without PLC, with every small change in the structure, the network will undergo many changes. Changing large networks that do not use PLCs can be costly in time and money.