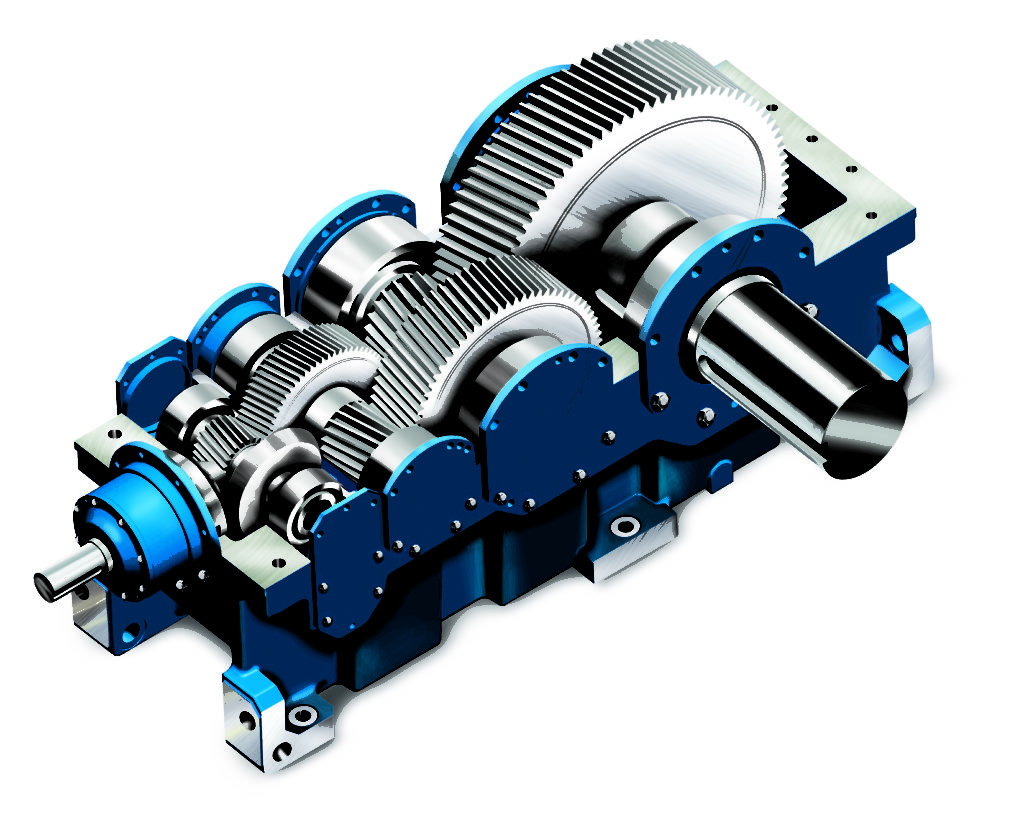

If we want to explain the Helical Gearbox or direct shaft gearbox in simple language, it is a device that includes several pairs of gears inside the shell and these gears are helical or spiral gears and rolling bearings on both sides of the bags. Are. Usually, the gears for these gearboxes are designed in spiral or simple form. The angle of the kits is diagonal with the axis so that more than one gear is engaged at any moment. This process causes the pressure to be distributed among all the gears and the device does not suffer from excessive pressure. Finally, the depreciation of the device is reduced. In these gearboxes, an output shaft is located precisely at the end of the electric motor.

A set of diagonal gears that have the ability to bear and transmit high power is called Helical Gearbox. This gearbox is also named a direct shaft gearbox, bull helical gearbox, parallel shaft gearbox, three-axis shaft gearbox, and four-axis shaft gearbox. High density, very high output torque, low noise performance and long service life are the best features of this type of gearbox.

The shell material of the Helical Gearbox is usually made of steel or cast iron and the shafts are also made of steel. The components of direct shaft gearboxes are also variable. In fact, they are designed as multi-axial based on their application and distance transmission. Some direct shaft gearboxes have two perpendicular gears that are made up of a pinion type. This model of gears can have the best conditions in changing the direction of the input torque by 90 degrees.

How the helical gearbox works

A helical gearbox has a pair of engaged gears so that the gears move in opposite directions. One gear is known as the driving gear and the other gear is the moving part. This process causes revolution and torque to be transferred from one axis to another axis. The operation of the helical gearbox is not complicated and is designed in a completely precise and principled way. Usually, these gearboxes are connected to electric motors with a power of 0.35 to 55 kW. The direct shaft gearbox has the condition of connecting to hydraulic motors. Pay attention that the level of performance of these gearboxes is very important and measured in principle.

How the helical gearbox works

Many questions have been asked about how the helical gearbox works. The truth is that conventional gears usually have a limited condition in terms of the contact surface, this process causes them to not endure in environments where the state of stress is high. In fact, gears fail quickly. The helical gearbox works in a different way. So that the gears have a specific angle that causes more stress tolerance, higher power and torque transmission, and less noise. The design of this gear style makes it easier to work with these gearboxes.

Lubrication of the direct shaft gearbox is one of the most important issues that help it work properly. Some gearboxes from certain brands are lubricated, so they no longer need lubrication. The purpose of lubrication of direct shaft gearboxes is to prevent damage and wear of moving parts. Correct lubrication makes the helical gearboxes be maintained precisely and properly. Choosing the right lubricant will greatly contribute to the long life of the helical gearbox. On the other hand, the uniform operation and high efficiency of the gearboxes have led to acceptable performance.

Advantages of helical gearbox

One of the important advantages of the helical gearbox is less rotation of the output shaft compared to the input shaft. This process causes the output power to be many times the input power. These gearboxes are designed both with and without flanges. In flanged models, the gearbox is directly coupled with the power generation source, that is, with the electric motor, while in flangeless models, the gearbox will need a belt and chain wheel to the production source.

Another advantage of the helical gearbox is its high strength. The resistance level of this system is so advanced that it is used in many industries. High torque is another advantage of a direct shaft gearbox. A high level of resistance and torque is generally one of the things that can ultimately contribute to a better result. These gearboxes have high performance and longevity and are also used for heavy industries.

The production of minimal noise is another advantage of the direct shaft gearbox. These gearboxes are highly efficient and work flawlessly at high speeds. The amount of vibration and tension in these gearboxes is low and they have trouble-free maintenance. On the other hand, the lubrication system of these gearboxes is very simple and has a low depreciation level.

Disadvantages of helical gearbox

The high price of helical gearboxes is one of their disadvantages. The manufacturer's brand affects prices, and in general, if high axial pressure is considered, these gearboxes may not function properly and require more resistant bearings. High efficiency is considered one of the important features of the direct shaft gearbox and has made it a good alternative compared to other gearboxes.

Helical gearbox maintenance

A helical gearbox, like other gearboxes, requires care and maintenance. These gearboxes need to be controlled by an expert team. This process helps prevent financial losses. The most important factor in maintaining the helical gearbox is lubrication and oil level. The oil level for these gearboxes should be checked periodically.

In fact, over time, the lubrication properties of the oil will decrease and eventually, the efficiency will decrease. Note that gearboxes should not be damaged. If unusual noises or strong vibrations are heard, the bearings should be checked and sometimes replaced. If the problem is with the gears, they will need to be replaced.

Oil leakage is another thing that can be seen for the direct shaft gearbox. Oil leakage causes the failure of gaskets and seals, and will ultimately have the best effect. If the electric motor is working, the output shaft does not have a standard rotation, which means the device does not work properly and eventually needs to be repaired.

It is necessary to check the condition of the oil every six months. Oils should be changed every three years. If the direct shaft gearbox is small, there is no need to change the oil during its operation. These transmissions will differ in terms of maintenance based on the model they have. Investigations show that the helical gearbox should be carefully examined and condition evaluated after a long working period.