What is Servo Motor?

The Servo motor is composed of two words servo meaning assistant steering and motor meaning drive. So a servo motor is a self-adjusting motor/actuator.

Servo motors are independent electric motors with a closed-loop mechanism that rotates around a shaft. A servo motor is a mechanical motor that can be used to move an arm or a wheel connected to its shaft in a desired direction and size at the desired speed, also It accepts speed changes quickly due to low inertia or low inertia (low resistance to changing the speed or changing the direction of the object).

A servo motor is generally an electric motor which contains a set of electronic circuits like drives next to it, and the electric motor containing the shaft is responsible for the rotation action. The electronic equipment is also responsible for the accuracy of the electric motor, and this accuracy includes angle control, acceleration control, speed control, etc. The control management method works by using three tools: an error detection device, an amplifier, and an error correction device.

Each element plays an important role in coordinating the reference quantity with the controlled quantity. When the set quantity is different from the reference quantity, the error detection device detects and reveals this error. Then it sends an error signal to the amplifier which is responsible for correcting the power. The error correction device changes the controlled quantity to match the reference quantity.

By mentioning an example and with a simpler expression, it can be simplified as follows: suppose you have a production line of carbonated water bottles, the bottles go through several stages to be distributed to consumers. For the first step, the inside of the bottles is filled with carbonated water, then their lids are sealed, and in the next step, each bottle is labeled by the manufacturer. At what point the bottles stop, at what speed and to what point they move forward, and the time they stop at each point, as well as the angle of their movement, are all done by the servo motor. Information about the exact location of the bottles, the angle of movement of each bottle, as well as the speed of their movement, is given to the servo motor controller by the sensor or encoder.

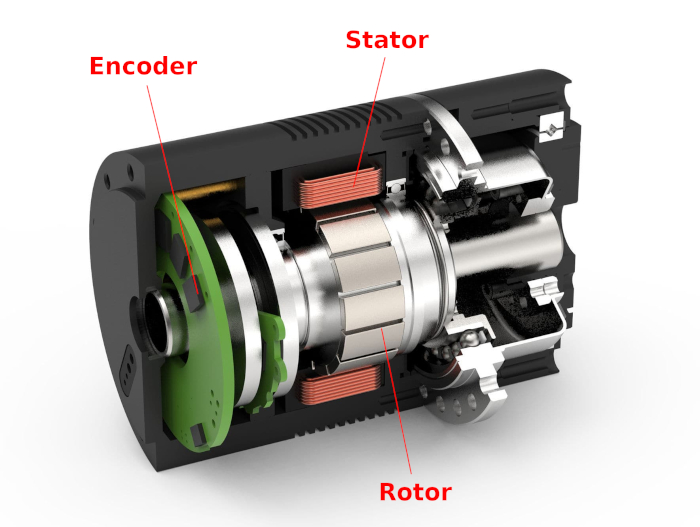

Components of servo motor

The servo motor consists of the following:

Electric motor: which is responsible for creating movement through its axis.

Control system: This system provides the possibility of controlling the movement of the motor by sending electrical pulses.

Drive system: It is formed by gears that may increase or decrease speed and torque.

Potentiometer: It is connected to the central shaft and always shows the angle at which the motor shaft is located.

What is the application of a Servo Motor?

Servo motors can be used anywhere where electric motors are used, but due to its high price compared to electric motors, servo motors are used only in places where the work is not done properly with ordinary electric motors and requires precision.

And the speed of doing it is high. Below we have Mentioned some devices and places where servo motors are used:

-

Textile machinery

-

Printing machines

-

5D and 3D cinema

-

Plastic injection machines

-

medical equipment

-

Metal, wood, and gold CNC machines

-

Machines and devices for the production of electronic components

What is Servo Drive?

Servo drives are used for both DC and AC motors, but in the industry, these early devices were generally used for DC. Because for many years high amperage control was done through SCRs. When transistors found the ability to control high Amperage and convert it to a higher frequency, AC servo drives became more popular. Older motors had a cooling fan that was attached directly to the shaft. When the motor was running at low speeds, the fan could not do the cooling job. Newer motors have separate fans that are installed to allow for the best cooling results. The constant voltage source feeds this fan so that the maximum RPM at any moment does not depend on the speed of these devices. One of the useful types of motors in the self-control system is a permanent magnetic (PM) type motor, its motor voltage can be AC or DC. This type of engine is similar to other previous types.

The response speed of servo drives to the error signal is high and they quickly accelerate the load, and the main difference between these devices and ordinary motors can be seen in reading the output feedback. This means that servo drives can be called closed-loop control systems. and electric motors can be called open-loop control systems.Servo drives have the ability to rotate from zero to 360 degrees. To rotate these devices, a pulse must be applied on the middle base,

which must have a certain frequency (usually 50 to 100 Hz) and its positive pulse width must be between 1 and 2 milliseconds. When the width of this pulse is 1 millisecond, the motor goes completely to the left, and when it is 2 milliseconds, the motor turns completely to the right, and when it is 1.5 milliseconds, the motor is locked in the middle position.

What is the difference between servo motor and servo drive?

As explained above, a servo motor is a structural unit of a servo system and is used with a servo drive. The servomotor includes the motor that drives the load and a position detection component, such as an encoder. A servo drive and servo motor can seem like they’re just about the same thing as they are often used in tandem together. In practice, they play different, but equally important roles in automation.

Introducing the famous brand of Servo motor and Servo drive manufacturer

Various companies have produced and supplied servo motors and servo drives, which we at Technomart sell reliable and reliable brands. Contact us to buy servo motor from Technomart. Also, if you need to buy servo drive, you can use our free consultation.

Some of the other existing brands of servo motor and servo motor in North America are as follows:

-

Siemens

-

Delta

-

Fatak

-

Kinko's

-

LS

-

Trio

-

HCFA

-

Dorna

Also, the following are some of the most prominent brands of servo drive manufacturers.

-

Siemens

-

Delta

-

Fatak

-

Kinko's

-

LS

-

Trio

-

HCFA

-

Dorna

Read more: What is servo drive and how does it work?